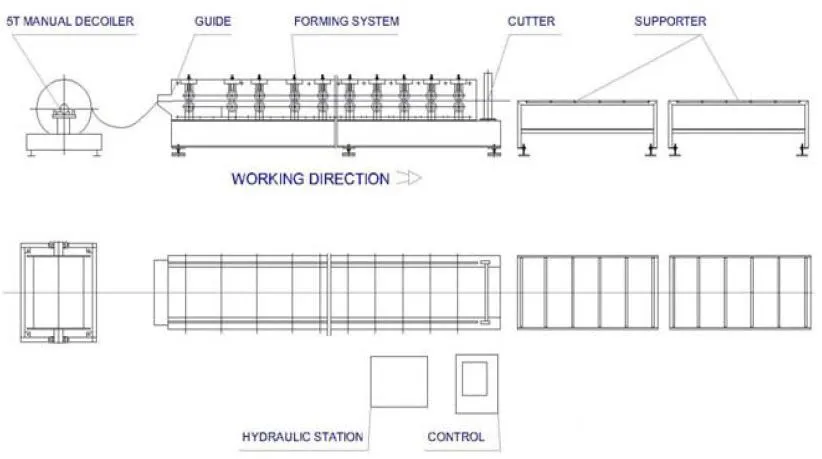

The operation steps of the machine are to put the rolled material into the forming machine through the material guide device, and gradually form it through the forming wheel. After reaching the product’s cross-sectional size, the product is cut by the cylinder blade cutting method. The cylinder drives the blade downward to cut the product. The length of the product is controlled by the encoder positioning method. The length error is small. The production line works normally while the product is cut. The whole process is not stagnant and is fast and smooth..

| Model NO. | BC20-200mm | Condition | New |

| Customized | Customized | Automatic Grade | Automatic |

| Structure | Horizontal | Transmission Method | Machinery |

| Description | Automatic Aluminium U Baffle Ceiling Suspend False | Working Material | Aluminum and Color Steel |

| Yield Strength | 235-345MPa | Punching | Single Hole and Double Holes |

| Thickness | 0.3-0.6mm | Width | 1010/900mm |

| Cutter Type | Hydraulic Cutting | Control System | PLC |

| PLC Brand | Panasonic/Delta | Decoiler | Manual/Hydraulic for Options |

| Applilcation | Cold Forming Sectional Steel | Size Changing | Semi-Automatic or Full-Automatic |

| Application | Roofing & Decking | Technical Support | Whole Life of Machine |

| Container Type | 40′ Gp | Transport Package | Naked |

| Specification | 1*40′GP | Trademark | FrameTec |

| Origin | China | Production Capacity | 600 Sets/Year |

Product Description

| Machine Quick Details | |

| Model Application: Automatic Aluminium U Baffle Ceiling Suspend false ceiling Roll Forming Machine for Ceiling Decoration | Condition: New |

| Type: Roll Forming Machine | Brand Name: Frametec |

| Applicable Materials: aluminum & color steel | Forming Speed: 10-50m/min |

| Warranty: 1 year | Place of Origin: China |

Features of the machine:

The operation steps of the machine are to put the rolled material into the forming machine through the material guide device, and gradually form it through the forming wheel. After reaching the product’s cross-sectional size, the product is cut by the cylinder blade cutting method. The cylinder drives the blade downward to cut the product. The length of the product is controlled by the encoder positioning method. The length error is small. The production line works normally while the product is cut. The whole process is not stagnant and is fast and smooth..

Applications:

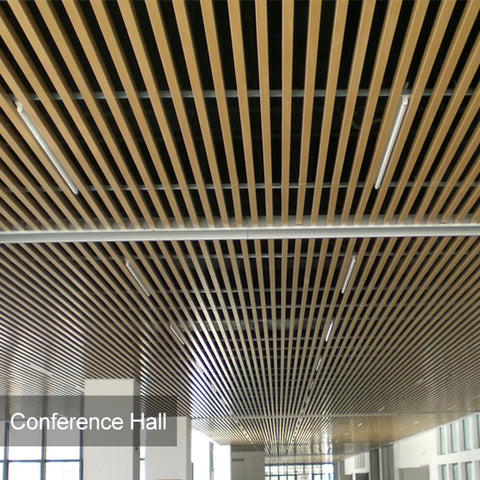

Shopping mall, Exhibition Center, Conference hall, Restaurant, Office & etc

MATERIAL:

Profile width: 20-200mm

Flange: 20-200mm

Thickness 0.3-1.2mm for aluminum coil

Thickness 0.27-0.45mm for color steel

Main Components:

1. Hydraulic decoiler with coiler car

Features: Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

Power: None;

Power of the open and closure of segments: Mechanical;

Power of rotation of segment: Pull by forming system;

Range of segment expansion: 450 ~ 520mm;

Max load: 1 ton

Feeding speed: depend on the roll forming machine speed;

2. Sheet guiding device

Features: Ensure smooth& precise material feed.

Components: steel plate platform, two pitching rollers, position stopping block.

The coil is guided in the correct position and passed to the roll forming equipment

3. Roll-Forming M/C:

The main frame of machine is welded separately and the outside wall is connected by screw after being rot blasted on the surface.

14 groups rollers . Roller Material is GCr15 mould steel being quenched treatment, with digital-controlled procession.

Roller Material is high grade Gcr15 steel, with digital-controlled procession.

Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

60mm thick independent precision guide column arch ensures long life of forming rollers.

- Fly Cutting

The cutting material is CR12MOV, and the hydraulic cutting method is adopted. The length dimension is positioned by the encoder. After the length dimension is adjusted, when the product reaches the set dimension, the cylinder moves with the product. The stroke switch instructs the cylinder to start driving the blade downward to cut the product. After completion, the cylinder automatically retracts. The product cutting length tolerance is guaranteed to be within ±1MM.

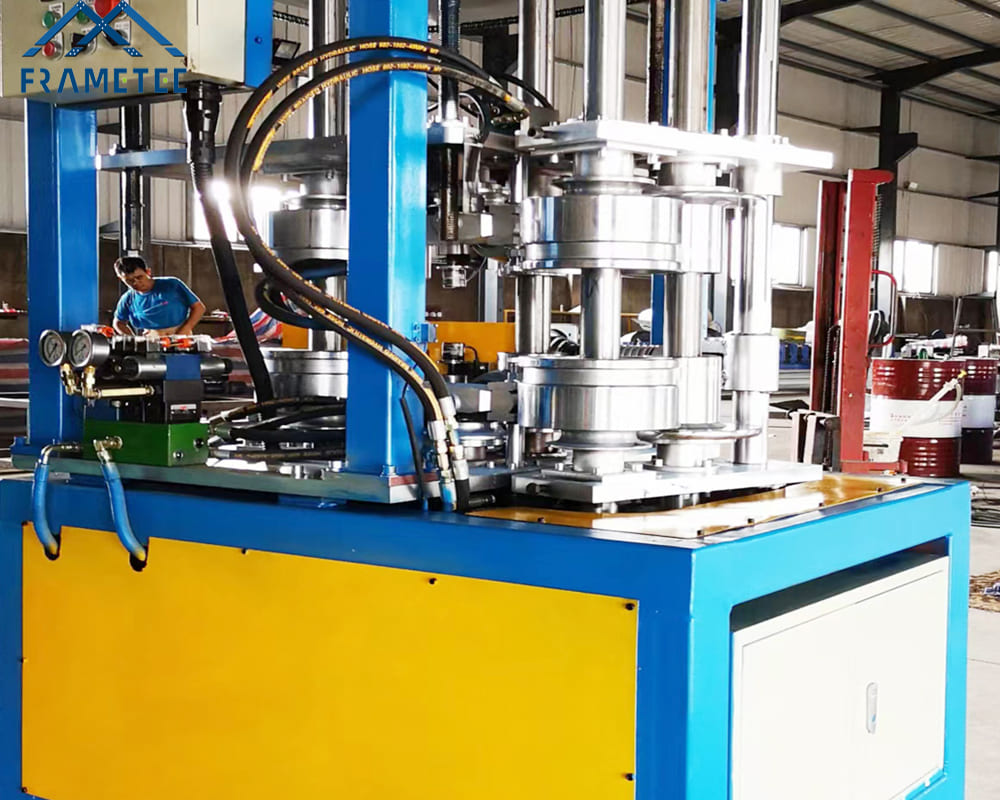

5.Hydraulic station:

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Adopted top brand hydraulic system components to ensure the stability and lifetime, avoid leakage.

Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.

6. Profile Stack

Un-power, 3m length, with roller on top stack for easy movement

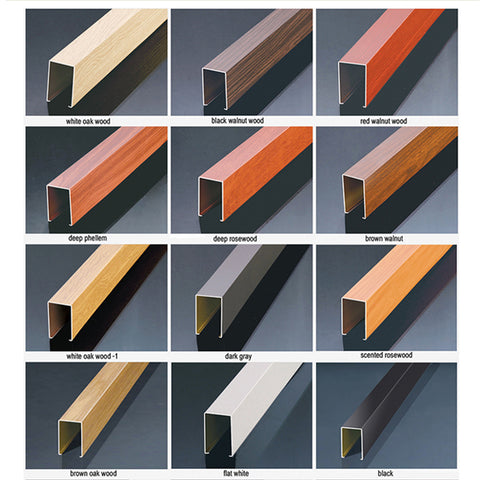

Profile Effects

Application: