Features of CZ purlin machine:

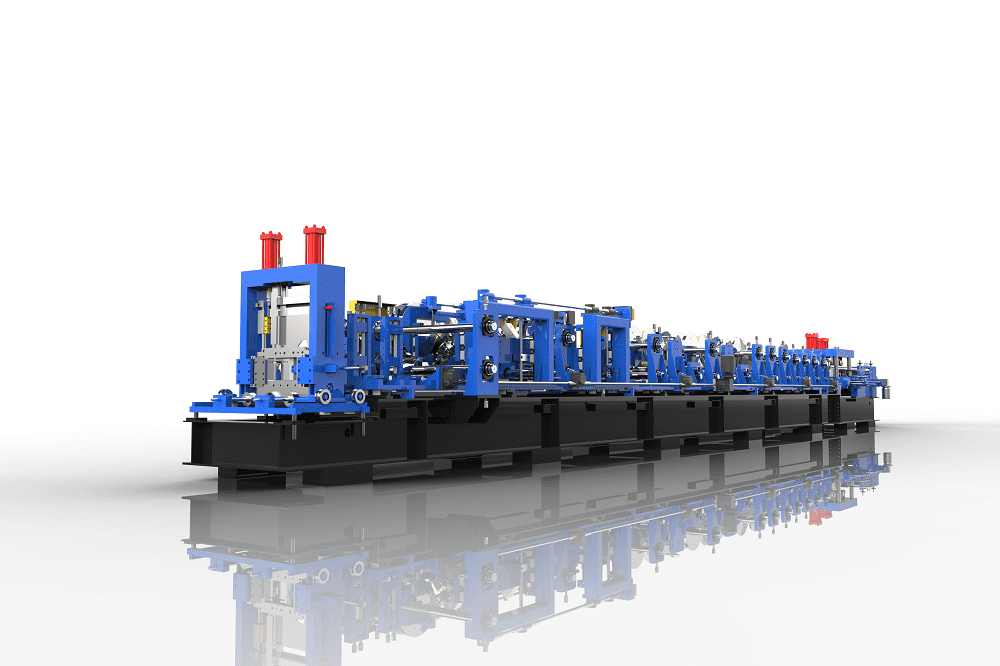

SX20 CZ purlin machine, available in both servo motor and motor versions to suit your production needs. Featuring 20 roll forming stations, including a flange forming 87-95° adjustable roller group, this machine guarantees precise and efficient performance for all your CZ profile needs. With 13 sets of CZ exchange modules in the motor version and 20A double-row chains for transmission in the servo motor version, you can expect smooth and reliable operation that delivers consistent results every time.

Designed with versatility in mind, the SX20 CZ purlin machine can handle a wide range of profiles, with widths ranging from 75mm to 300mm. Whether you’re producing standard C or Z profiles or complex custom profiles, this machine is up to the task. Plus, with its sleek and modern design, the SX20 CZ purlin machine looks great in any production environment.

Investing in the SX20 CZ purlin machine means investing in top-of-the-line technology that’s built to last. So why wait? Join the ranks of satisfied customers who have already made the switch to the SX20 CZ purlin machine and experience the difference for yourself.

| Machine Quick Details | |

| Model number: SX20 | Condition: New |

| Type: C/Z Purlin machine | Brand Name: Frametec |

| Max Production Capacity: 30m/min | Power(W): 22KW |

| Warranty: 1 year | Place of Origin: China |

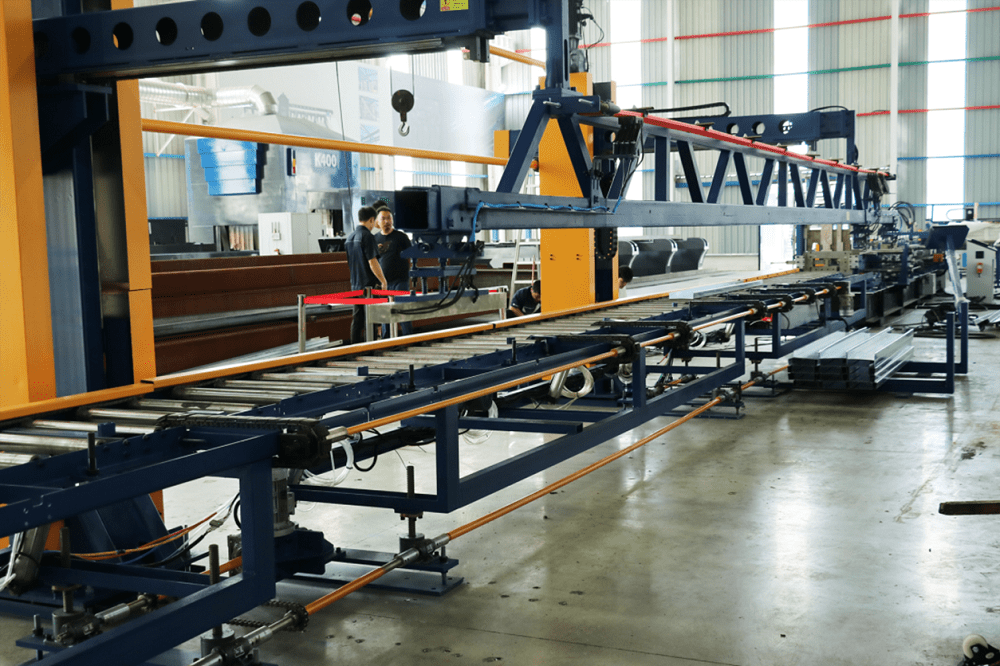

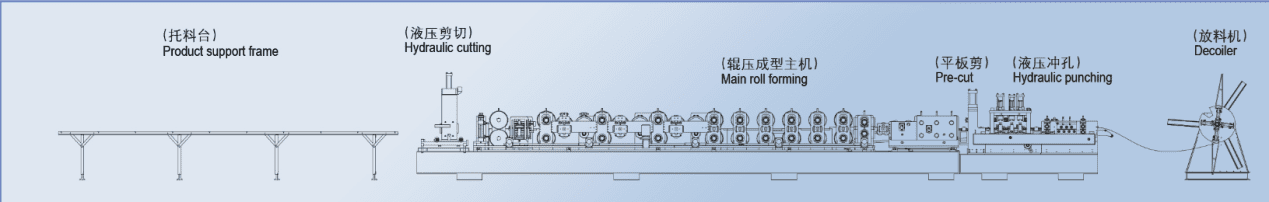

Flow chart: De-coiler – Leveling device — pre- punching and pre-cutting – roll forming parts – stack

Main features of quickly change CZ purlin roll forming machine

The Advantages of CZ purlin machine AUTOMATIC size-change type are as follows:

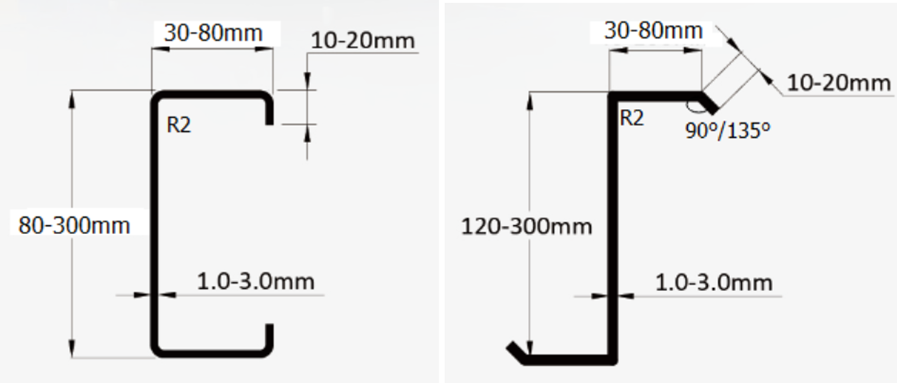

1.Produce different purlin size(C80-300/ Z120-300) without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

Main Components:

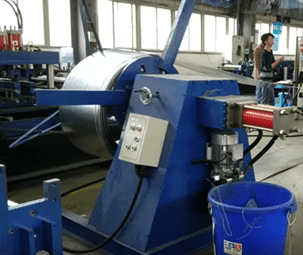

1. Hydraulic De-coiler

De-coiler Type: automatic fasten and loosen

Weight capacity: 6T

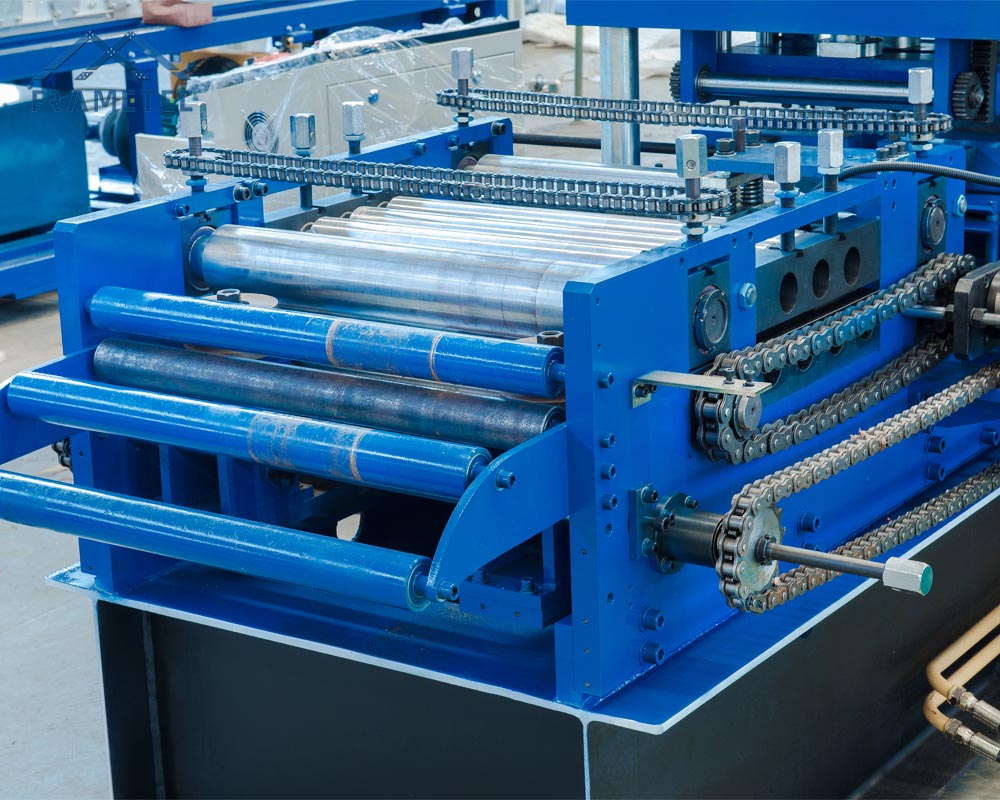

2. Feeding and Leveling Device:

It used for making the material flat before feeding into the roll forming machine.

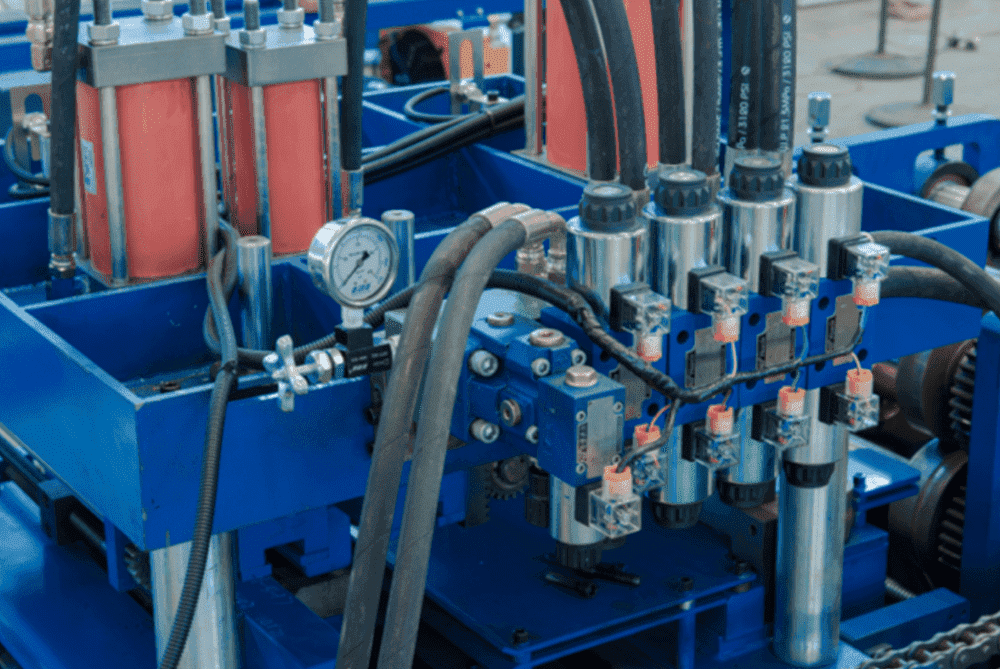

3.Pre-punching device

Punch on flat sheet. PLC control punch quantity and horizontal position; vertical position adjust by manual.

Web punching quantity& size: as per customer`s requirement

Flange punching quantity&size: as per customer`s requirement

Punching bar and punching die can be changed easily

4.Pre-cutting device

It used to cut raw materials before roll forming.

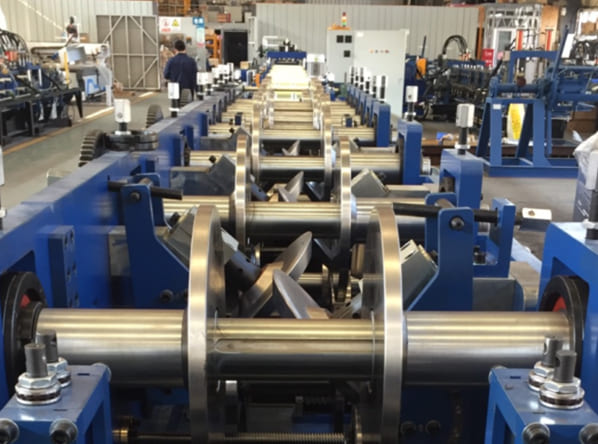

5.Main roll former

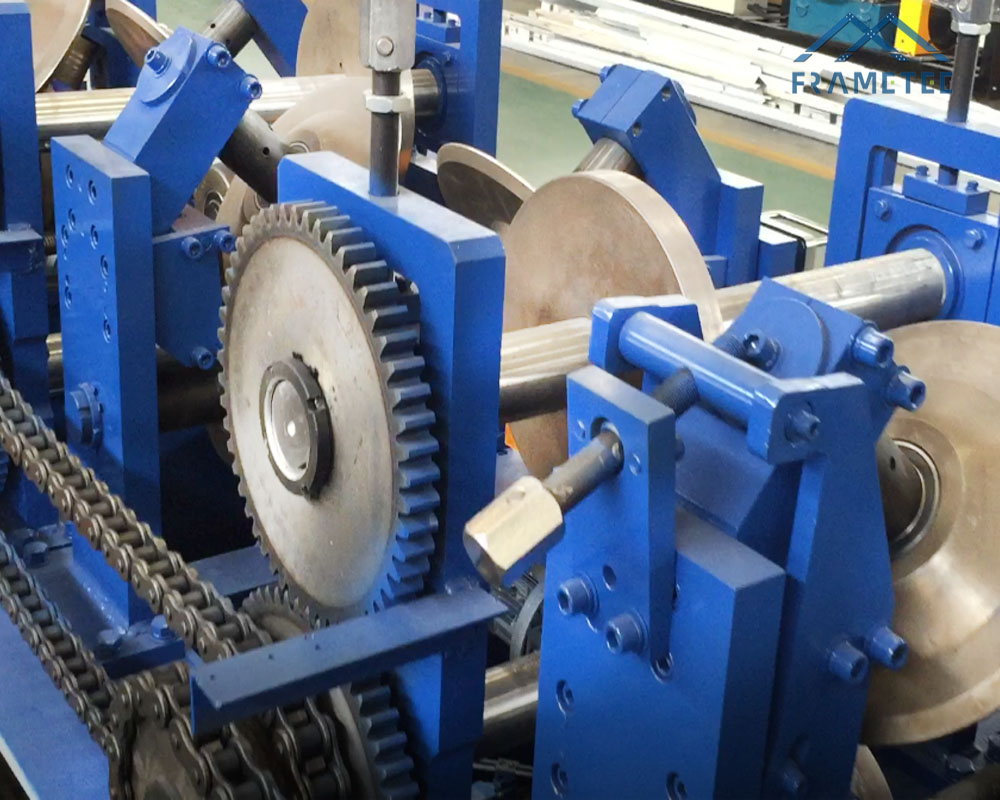

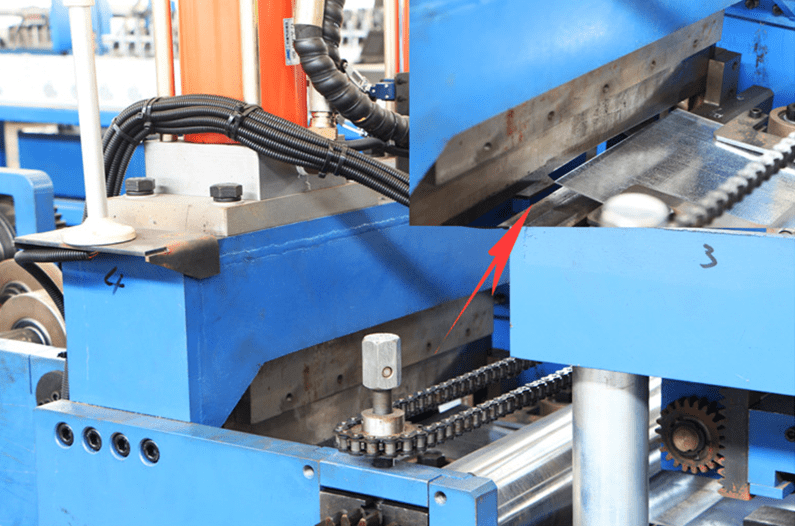

Driven type: By chain

Max Speed of forming: 30m/min

Roller : About 19 groups rollers

Roller Material is Cr12 mould steel;

Diameter of down roller is around 360mm

Shaft: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product. Diameter of main shaft: ø95mm (as per final design)

Material of main shaft : 40Cr

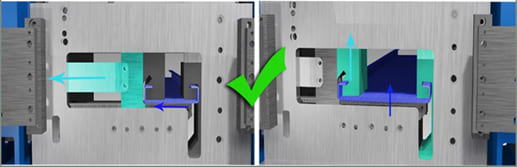

Changing sizes: Automatic or Semi Automatic

Adopt fast C/Z interchanging system

Quick C/Z interchanging only with 3 steps,within 5 -15 mins.

6.Hydraulic Cutting

Adopt our innovative cutting system, CZ integrated & adjustable cutting mold do not need to replace cutting mold when purlin sizes change.

7.Product Support Frame —1set

8.PLC Control System

Control the quantity &punching length& cutting length automatically

The Machine will be stopped while it is punching and cutting

Automatic Length measures and quantity counting (precision +- 3mm)

Profile effect:

Our Factory

Why Choose us:

13 years’ manufacturing experience in CZ purlin roll former

Competitive price and good quality

One year free warranty

Fast response of after sale service

Auto web size changing from 80mm to 300mm in 2 minutes

Can be customized by clients’ requirements

Easy operate and easy to maintain

Self-developed of post cutter, one blade to cutter all size of final products