Features of the machine:

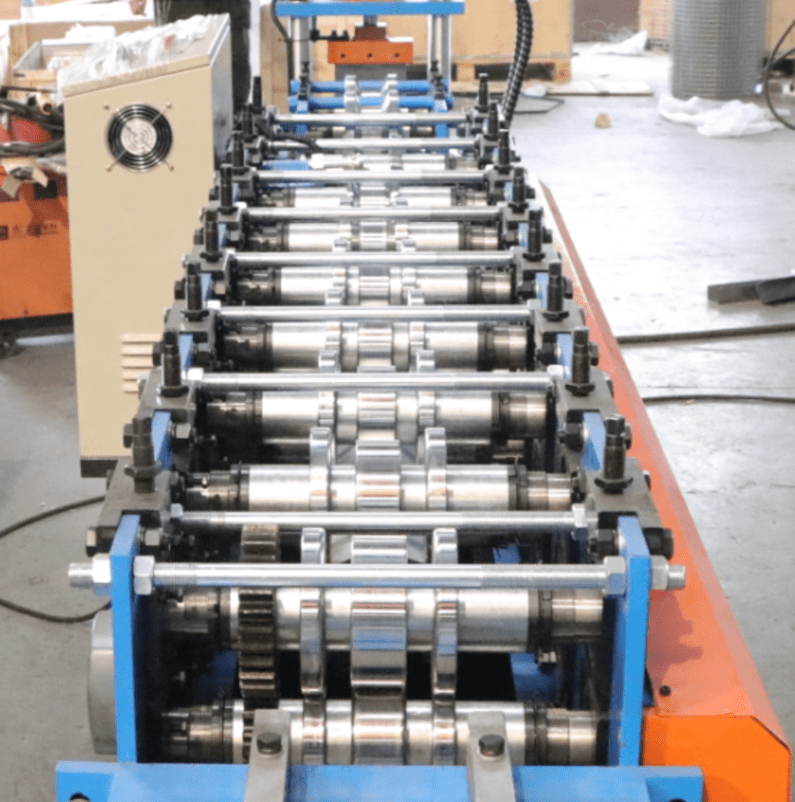

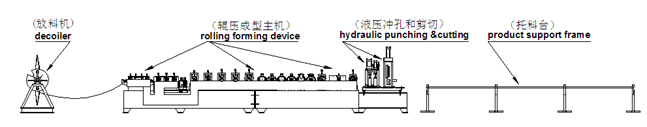

Our YX44mm Door Jamb door frame roll forming machine consists of decoiler, feeding and levelling device, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).

Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

| Machine Quick Details | |

| Model Application:door frame machine | Condition: New |

| Type: Roll Forming Machine | Brand Name: Frametec |

| Applicable Materials: PPGI | Forming Speed: 20-25m/min |

| Warranty: 1 year | Place of Origin: China |

Flow chart: De-coiling the sheet→Guiding sheet→Hydraulic Punching System→Roll forming→post cutting →Product to the run out table

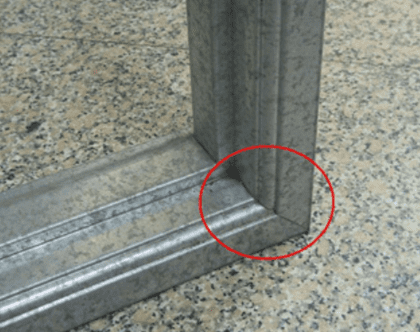

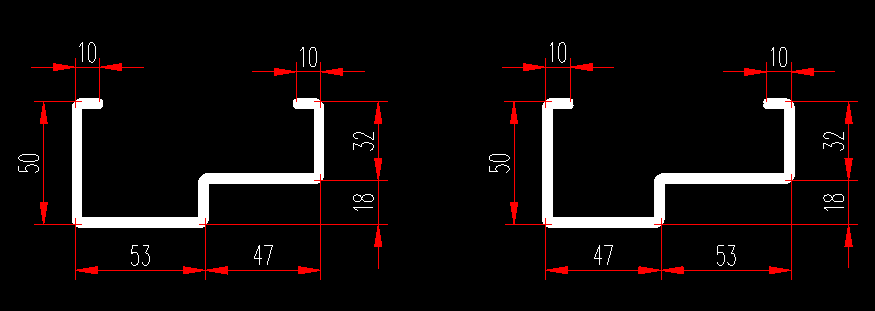

PROFILE

MATERIAL:

1 ) Profile Size Adjustment: Roller Sleeve Change type

2 ) Suitable Coil Thickness: 1.5 mm

3 ) Suitable Raw Materials: galvanized steel sheet, galvanized color sheet

4) Yield strength of raw material: Q235Mpa

Main Components:

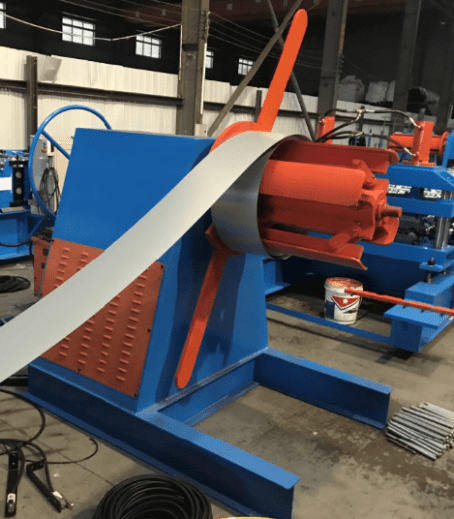

- De-coiler

Capacity: 5 tons

Diameter of inner: 600mm

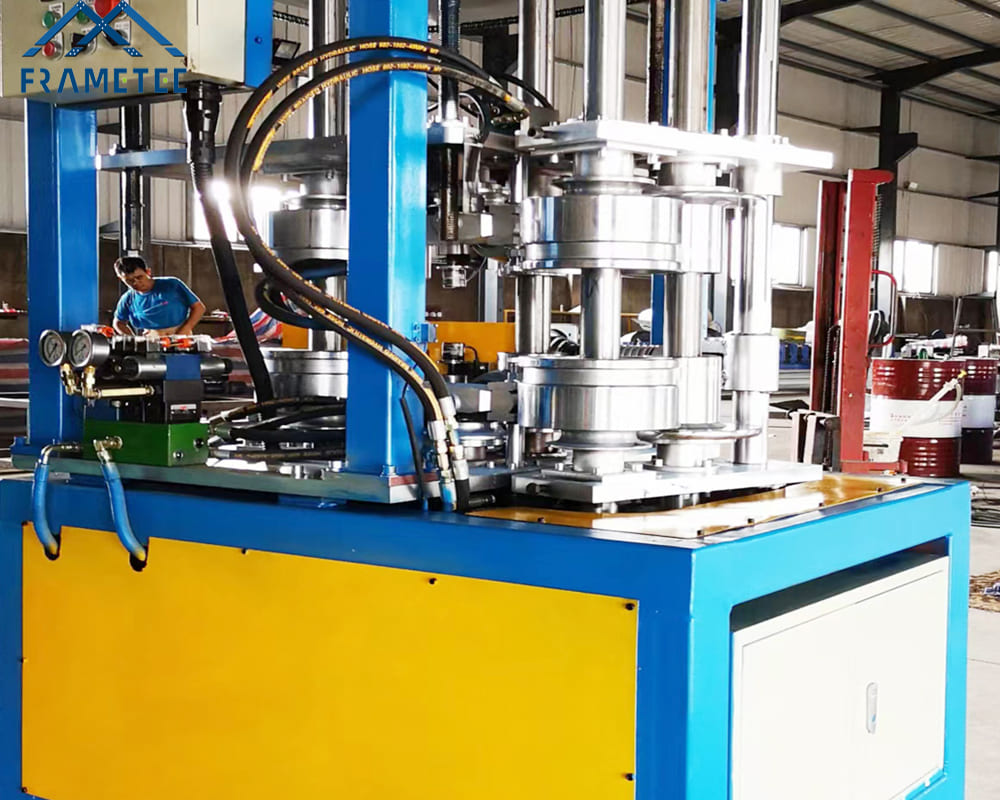

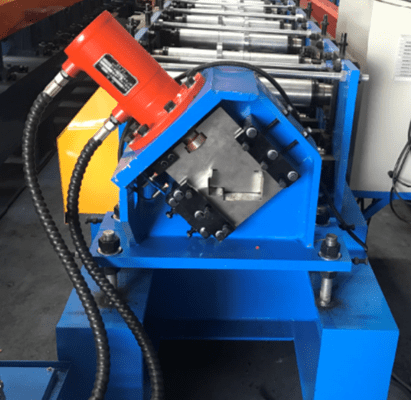

2. Pre-Punching System

1) 1 set of 5 cylinders punching device

2) 10 sets of punching dies

3) Punch and die materials: Cr12, finishing, heat treatment

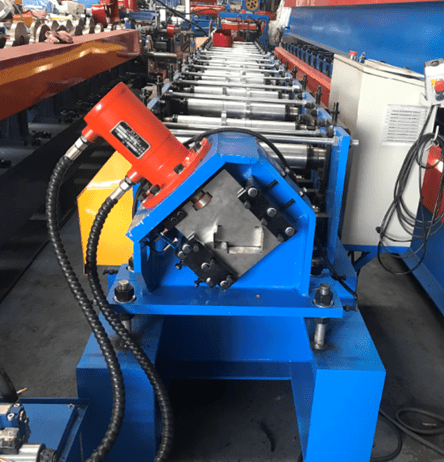

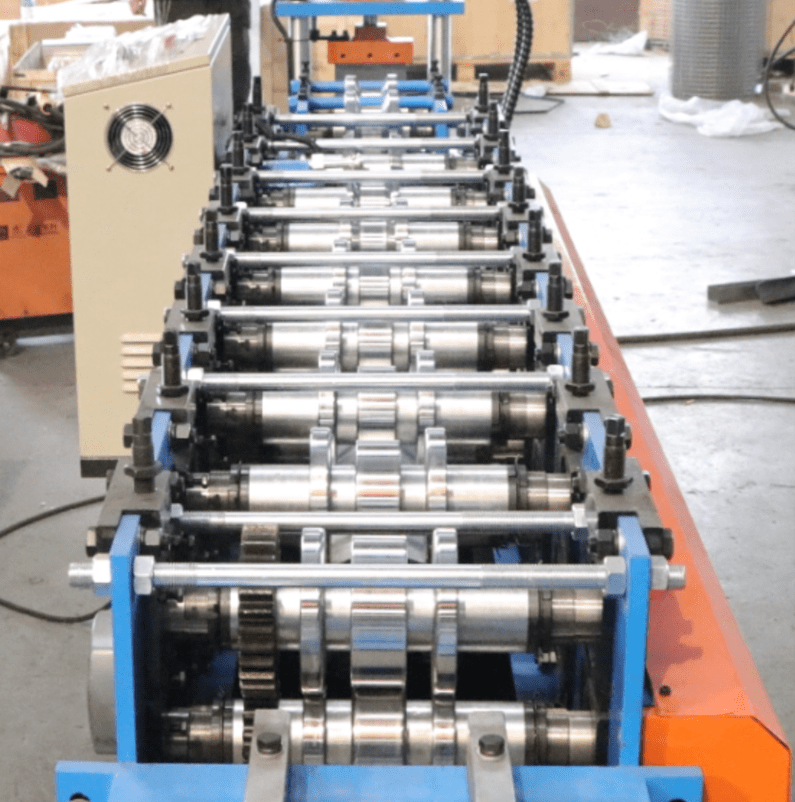

3. Roll-Forming M/C:

- The main frame of machine is welded separately and the outside wall is connected by screw after being roto blasted on the surface.

- Roller Material is high grade No.45 forged steel, with digital-controlled procession.

- Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

- The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool. So that ensures long life of forming rollers.

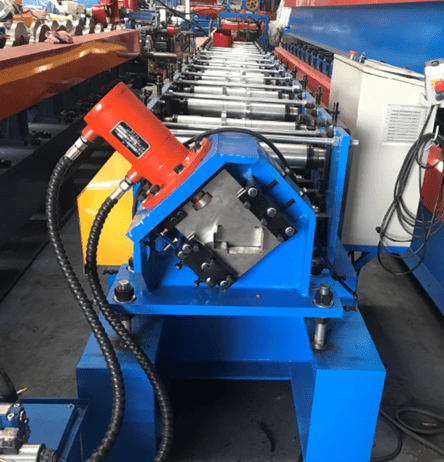

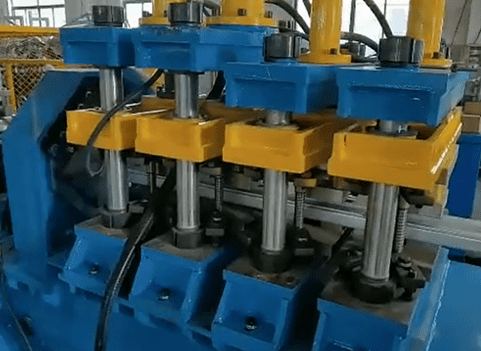

4. Hydraulic Post Cutting

1) Adopts post cutting, Stop to cut;

2) Two sets of cutting tools, one set for each specification

The cutting blade material is Cr12 with quenched treatment.

3) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product deformation. Cutting length tolerance is ±1mm.

5) The power of cutting is provided by hydraulic station.

6) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the product automatically. Finish this action, machine will run again continuously.

5. Hydraulic station:

1) It supplies the power for the hydraulic cutter.

2) Hydraulic motor power: about 7.5kw

6. Profile Stack

1) They are used to Collect the final product and final products are convenient to be stacked by workers.

2) Support length: 3 meters.

3) Quantity: 1 set

Machine Packing

Profile effects: