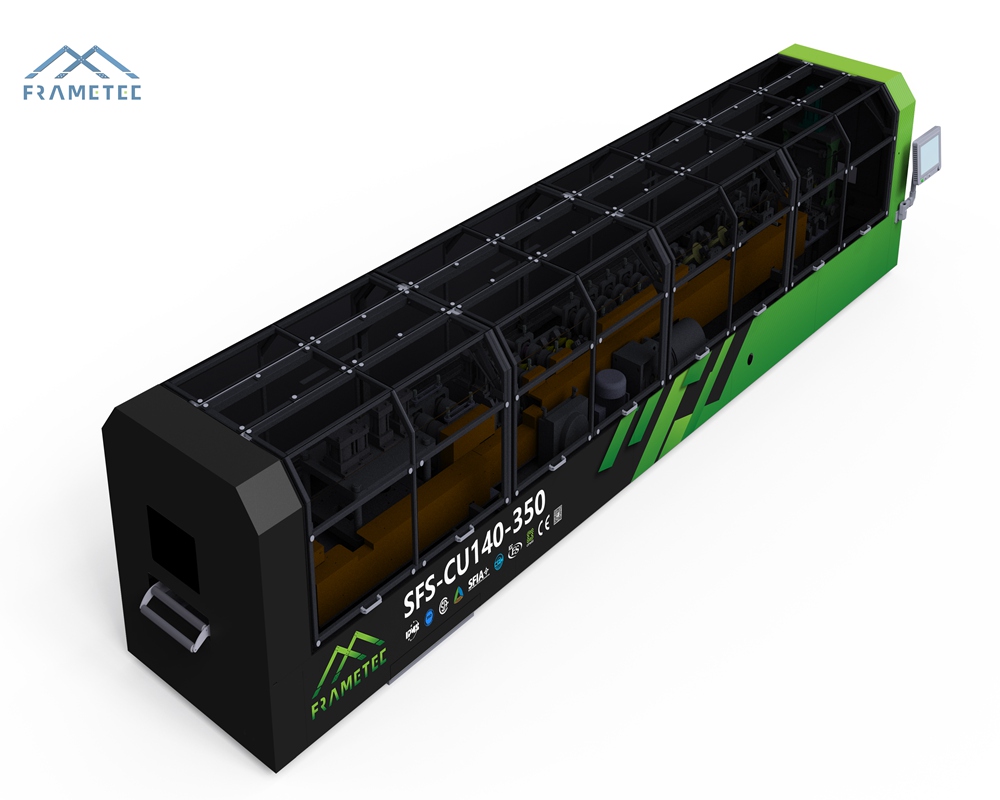

If you are seeking a highly efficient LGS machine capable of manufacturing heavier and wider framed sections and trusses with remarkable ease, the SFS-CU75-200 is undoubtedly the optimal solution for your needs. This state-of-the-art machine boasts the capability to produce profiles with widths ranging from 75mm to 200mm and thicknesses reaching up to 1.60mm, ensuring versatility and precision in every application.

The SFS-CU75-200 is specifically engineered for the CU stud & track system, incorporating advanced features such as dimple punching and web notch capabilities. This design provides unparalleled flexibility in panel assembly, making it an ideal choice for regions where the CU system is approved by local building codes. Should your area adhere to these standards, the SFS-CU75-200 is the direct and most effective choice for your construction needs.

Applications for this versatile machine encompass the construction of walls, floors, and roofs for 1 to 5-story residential buildings, modular houses, transportable units, light commercial structures, and customized buildings such as solar panel frames. With its impressive range of capabilities and adherence to modern building standards, the SFS-CU75-200 is poised to revolutionize your construction processes..

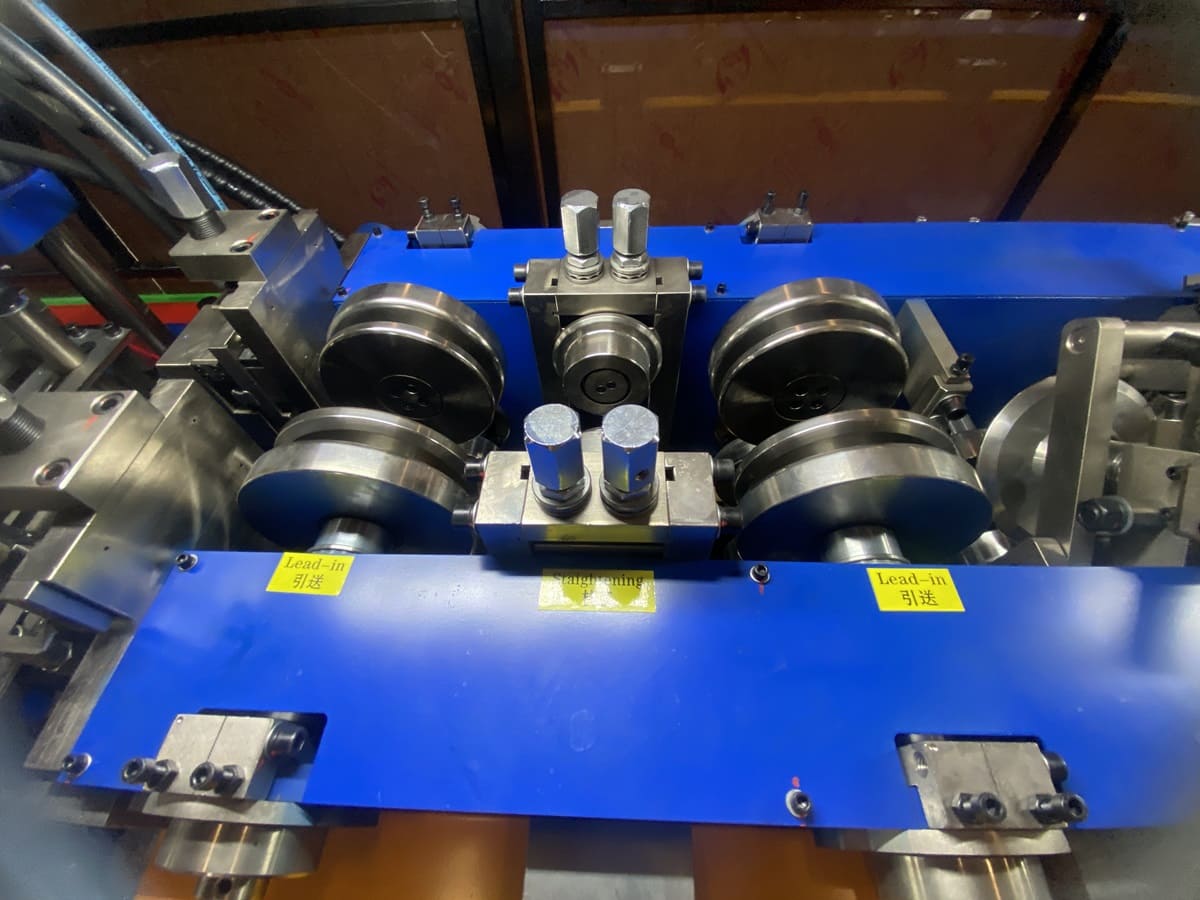

Machine Part

Ⅰ、Specifications

| Profile Shape | C and U |

| Profile Size | 75-200 mm |

| Material Thickness | 0.8-1.6 mm, G300-G450 Zinc-Alum Steel Coil |

| Operation System | 21 inches Touchable Screen |

| Production Control System | Self-devoloped FrameTec LGR1 machine controlling Software |

| Design Software | Vertex BD/ Framebuilder MRD / Strucsoft & etc. |

| Comprehensive Machine Speed | Joists: 500 m/hr Walls: 800 m/hr |

| Max. Machine Speed | 2,150m/hr |

| Punching, Cutting Mould | Service Hole, Dimple, Web Notch, Shear. |

| Hole Punching Accuracy | ± 0.5 mm |

II. Machine Video

III. Machine Main Features

| Classical LGS machine models for 10+ years, very stable and with high speed production speed | The SFS-CU75-200 produces wall frames, trusses and joists for residential and light commercial building quickly economically |

| Advanced hydraulic and punching functions for high productivity and versatile components production such as trusses, walls and joists | An auto-gauging system that automatically adjusts gauge range to increase overall productivity for steel thickness from 0.8 -1.60mm |

| High line speed results in the accelerated cold formed steel framing and truss manufacturing output | Smart production data reporting to enable daily production management, and technical diagnostics to improve efficiency |

| High line speed results in the accelerated cold formed steel framing and truss manufacturing output | Self developing control system base on the market feedback that can meet your requirement well & with good after sales support |

IV. Machine Details

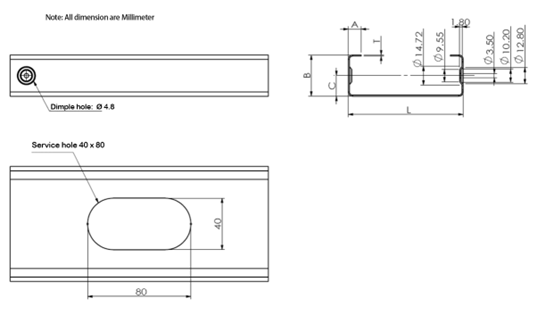

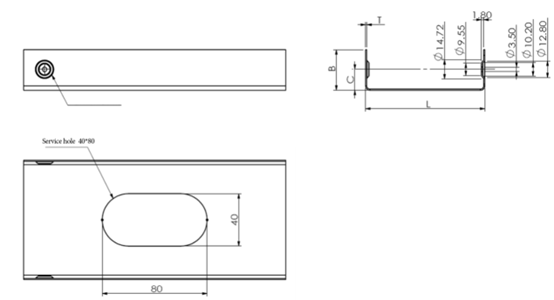

STANDARD METRIC SIZES

| Section Size | 75mm | 89mm | 92mm | 102mm | 140mm | 203mm |

| Web Width | 75mm | 89mm | 92mm | 102mm | 140mm | 203mm |

| Flange Height | 32 to 51mm | 32 to 51mm | 32 to 51mm | 32 to 51mm | 32 to 51mm | 32 to 51mm |

| Service Hole *1 | 40*80mm | 40*80mm | 40*80mm | 40*80mm | 40*80mm | 40*80mm |

| Dimple hole *2 | 4.8mm | 4.8mm | 4.8mm | 4.8mm | 4.8mm | 4.8mm |

| Thickness Range | 0.8-1.2mm | 0.8-1.6mm | 0.8-1.6mm | 0.8-1.6mm | 0.8-1.6mm | 0.8-1.6mm |

V. Profile Effect & Application

VI. Why Choose FrameTec

FrameTec is a specialized manufacture focusing in high quality roll forming equiments for the construction of light steel frame structure & cold formed steel structures.

Since 2009, FrameTec insists on cooperating with customers as a partner and actively provides effective solutions to ensure reliable product performance, advanced technology and easy operation, and promote users to a higher position in the fierce market competition.

All Frametec machines have a built in Windows based machine control which accepts a basic CSV file from a range of design software options that link to our machine. This gives freedom of choice to the customer.

FrameTec specializes in Designing and Manufacturing Steel Framing Machines for Wall Panels, Trusses and Floor Joists in:

- Residential and Commercial buildings

- Steel framed systems for modular & prefabricated buildings

- Walls framed for low and high rise buildings

- Walling, floors, beams, roofing, kitchen & bathroom pods

- Storage, recreational, transportable dwellings

FrameTec, the intelligent manufacturing solution provider for multi-storey prefabricated buildings !