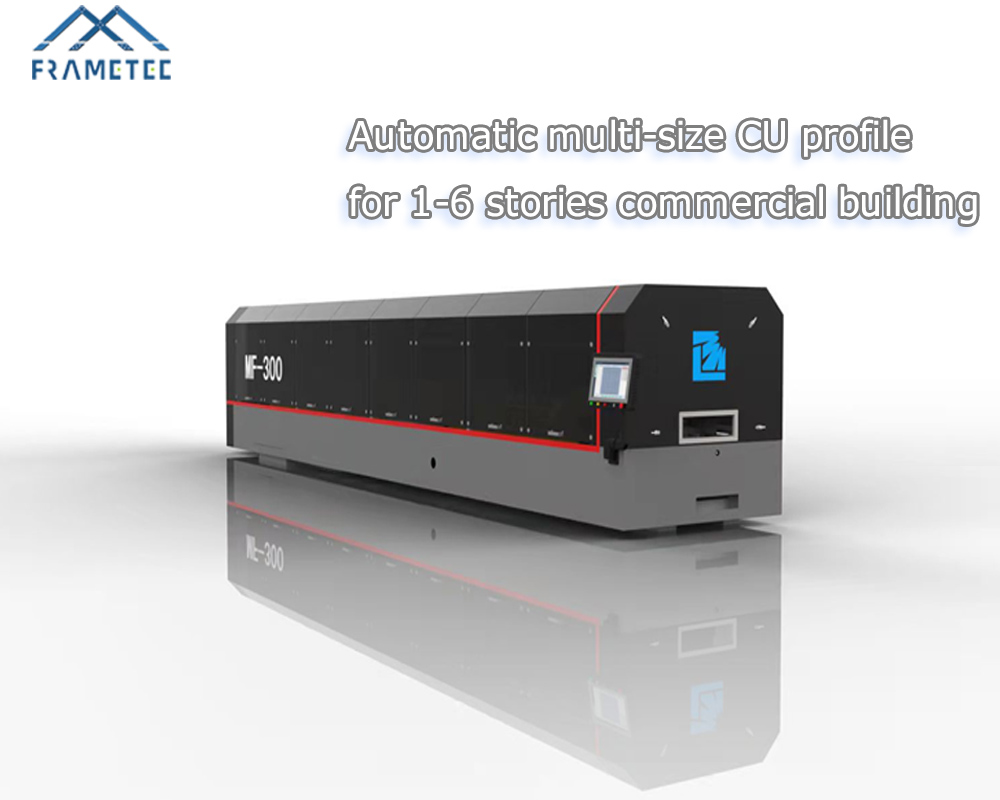

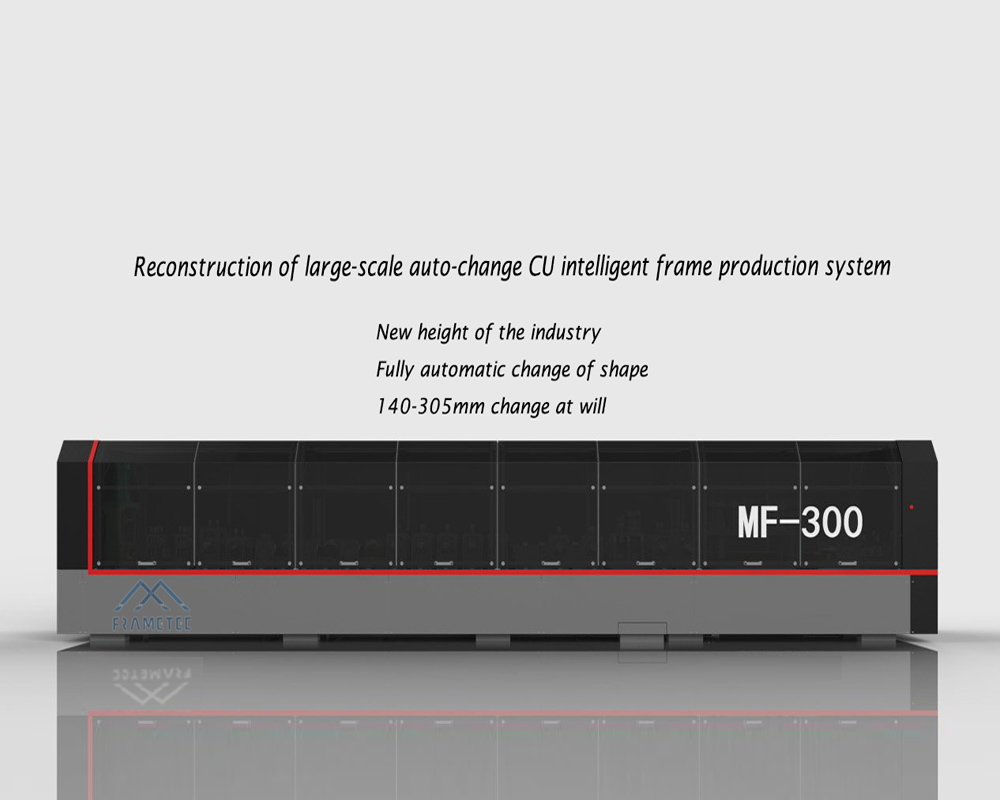

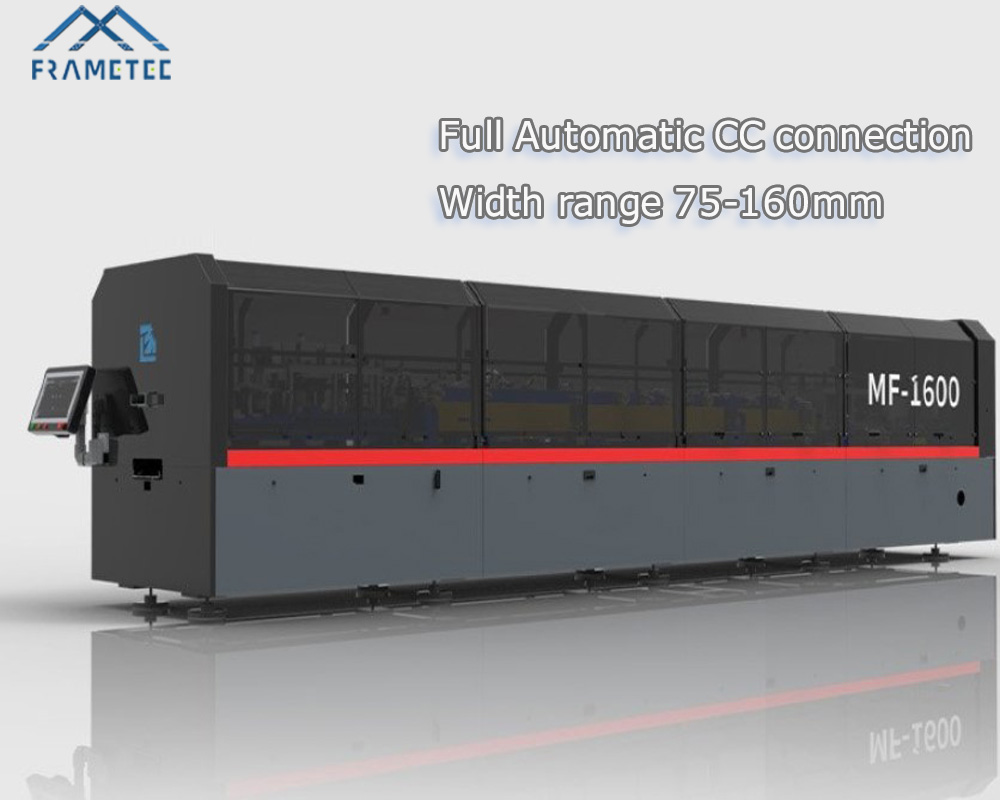

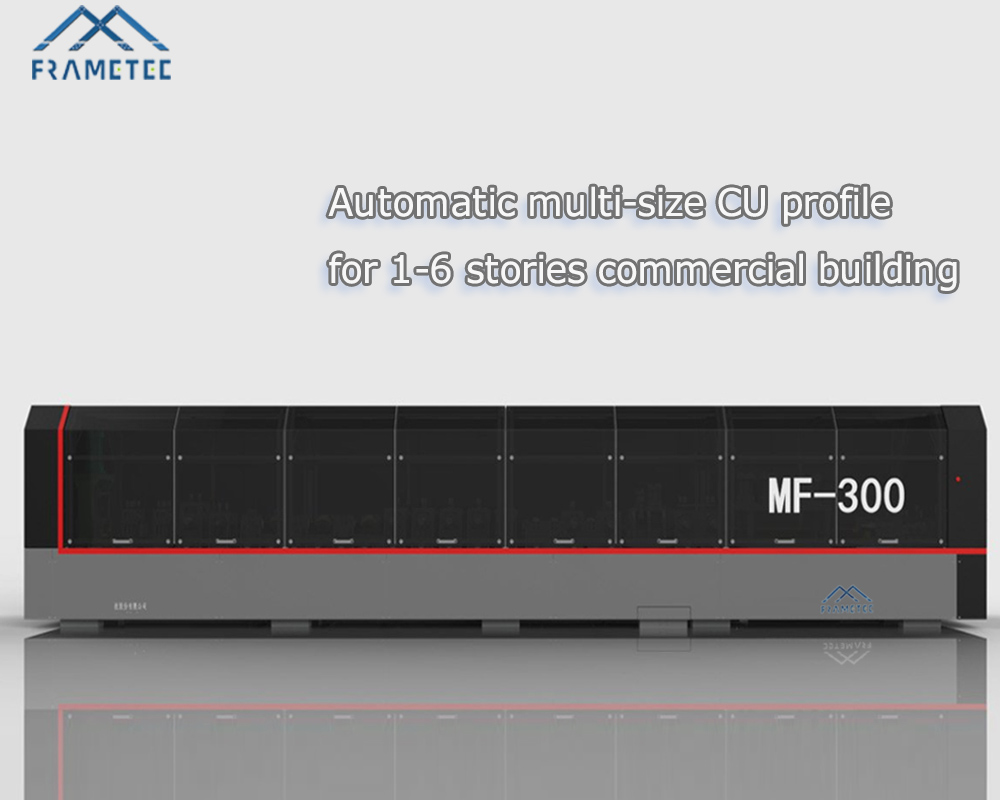

SFS-CU140-305 is called “super light steel frame machine” or “flexible 3D steel framing machine”. Which is truly multi-purpose machine. It allows you to manufacture frames, panels or floor joists – with sections from 140 to 305mm

Starting from the low cost of investment, a single profile machine can meet the initial needs; but from a professional and long-term point of view, the best choice to match with multi function machine, which is handy for low-rise, multi-storey, interior walls, exterior walls, American standard system, and Australian standard system.

Own it, go where others dare not go

Create a height that no one else has reached

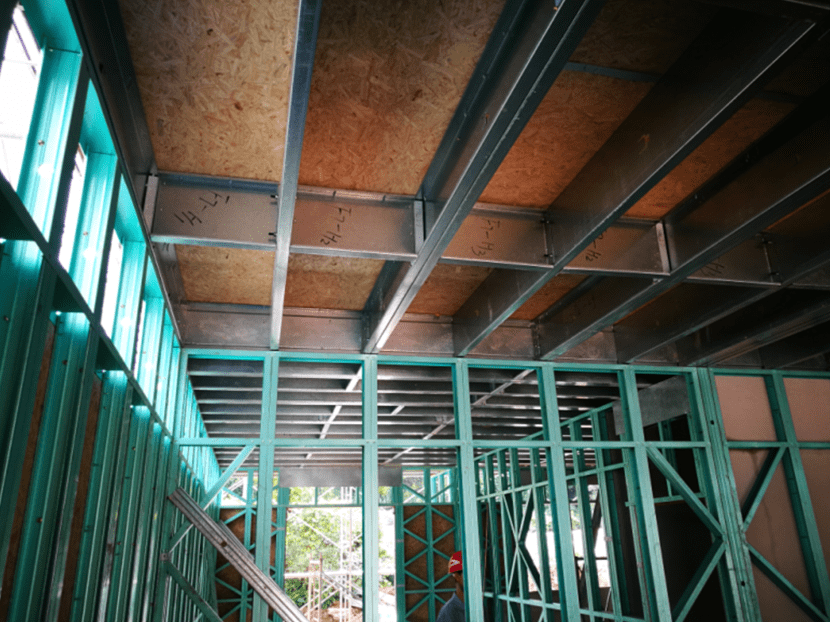

Applications: construction walls and floors for 1–6 level residential, light commercial construction, commercial construction and custom building like Solar Panel Frames.

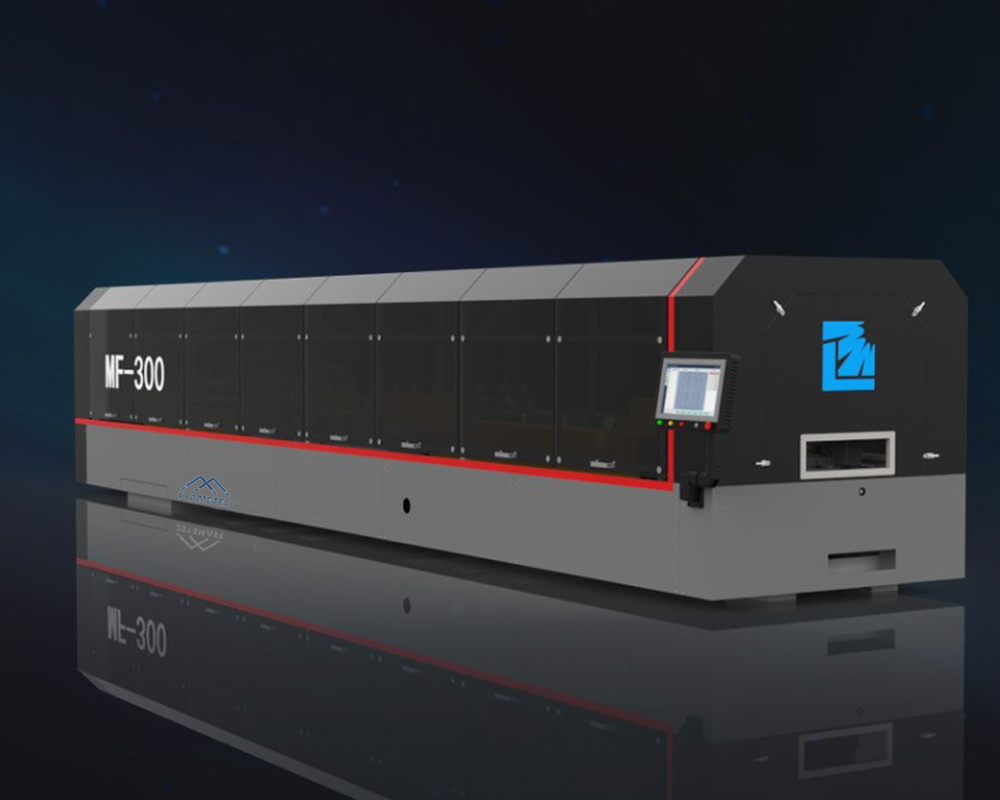

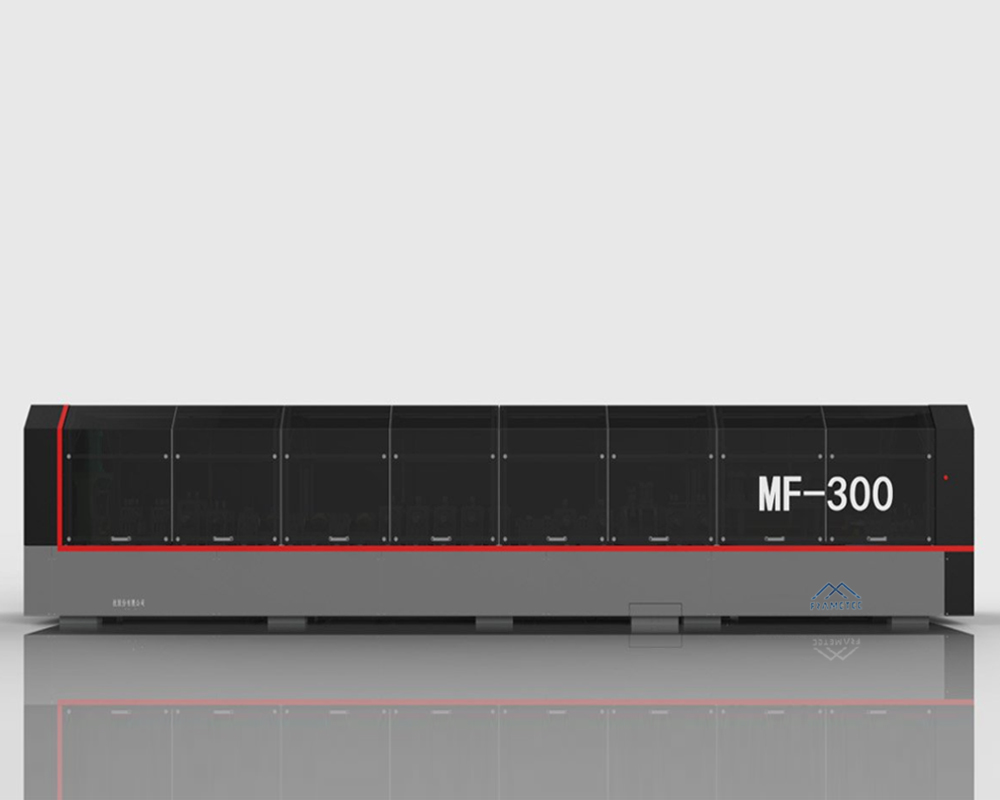

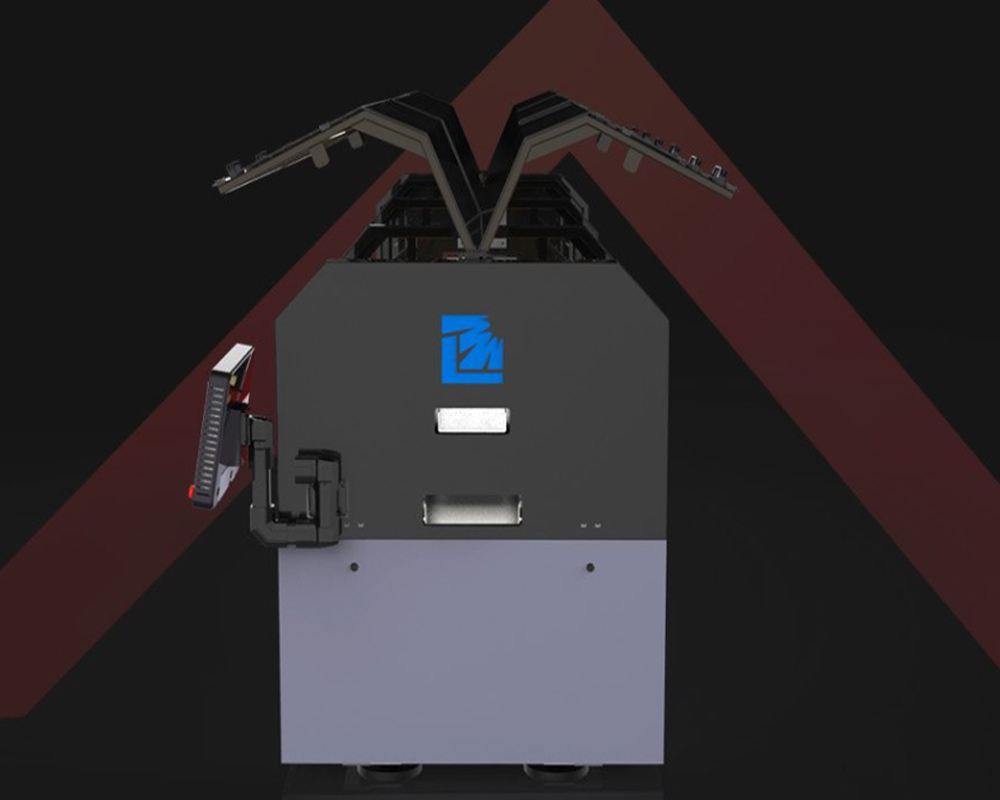

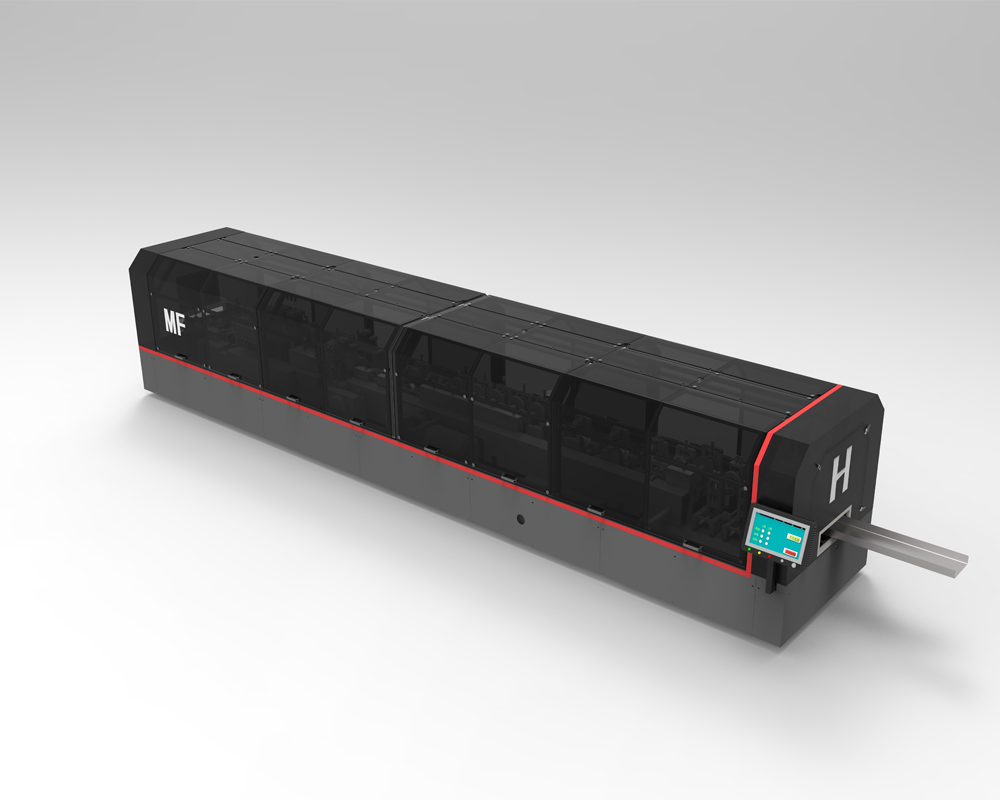

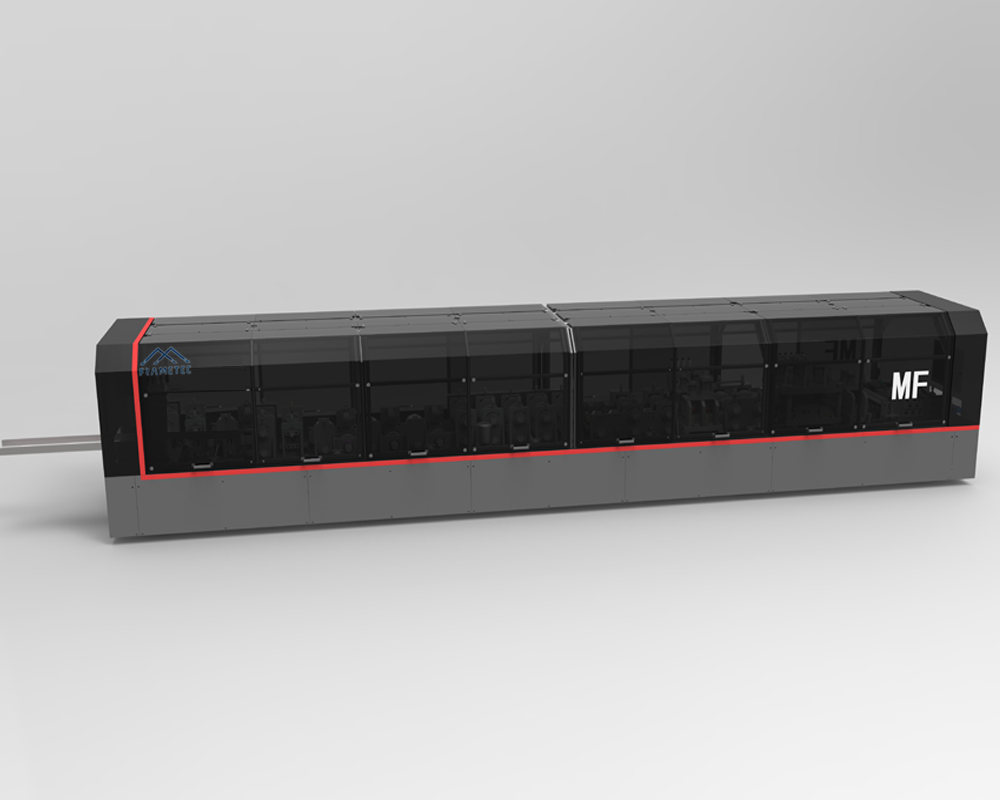

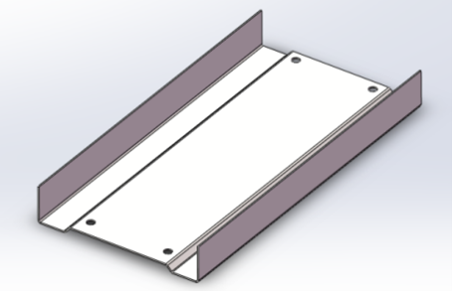

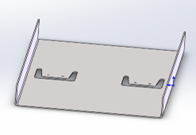

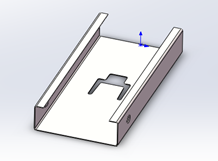

Machine Part

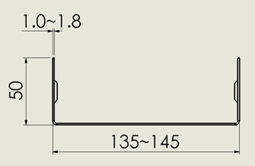

Ⅰ、Specifications

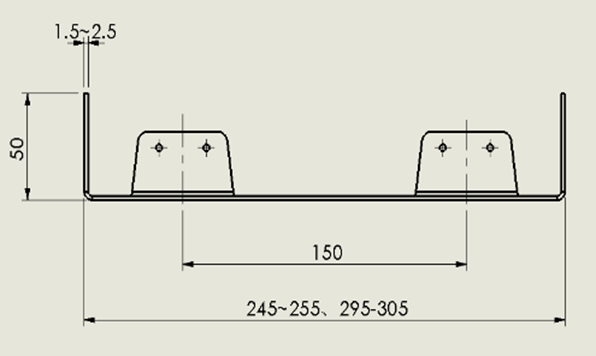

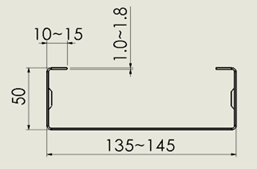

| Profile Shape | C and U |

| Profile Size | 135-305 mm |

| Material Thickness | 1.0-2.5 mm, G300-G450 Zinc-Alum Steel Coil |

| Operation System | 21 inches Touchable Screen |

| Production Control System | Self-devoloped FrameTec LGR1 machine controlling Software |

| Design Software | Vertex BD/ Framebuilder MRD / Strucsoft & etc. |

| Comprehensive Machine Speed | Joists: 500 m/hr Walls: 800 m/hr |

| Max. Machine Speed | 2,150m/hr |

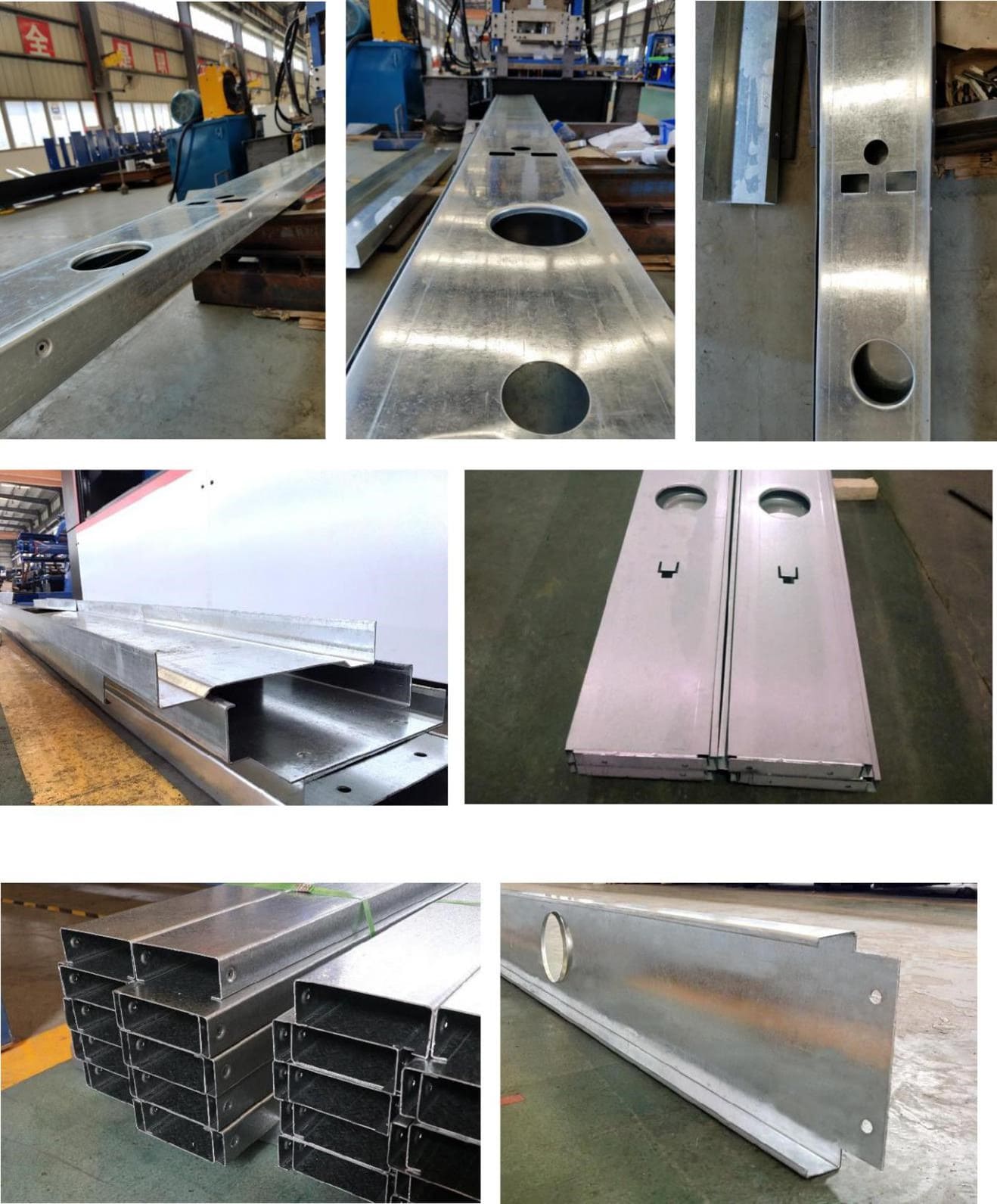

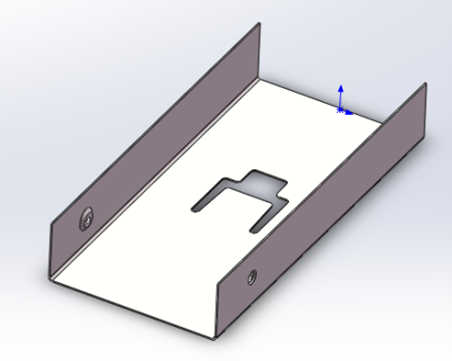

| Punching, Cutting Mould | Fixing tabs, Web hole, Service Hole, Dimple, Web Notch |

| Hole Punching Accuracy | ± 0.5 mm |

II. Machine Video

III. Machine Main Features

| Classical LGS machine models for 10+ years, very stable and with high speed production speed | The SFS-CU140-305 produces wall frames, trusses and joists for residential and light commercial building quickly economically |

| Advanced hydraulic and punching functions for high productivity and versatile components production such as trusses, walls and joists | An auto-gauging system that automatically adjusts gauge range to increase overall productivity for steel thickness from 1 -2.5mm |

| High line speed results in the accelerated cold formed steel framing and truss manufacturing output | Smart internet connectivity provides cloud-based data reporting to enable real-time production management, and technical diagnostics to improve efficiency |

| High line speed results in the accelerated cold formed steel framing and truss manufacturing output | Self developing control system base on the market feedback that can meet your requirement well & with good after sales support |

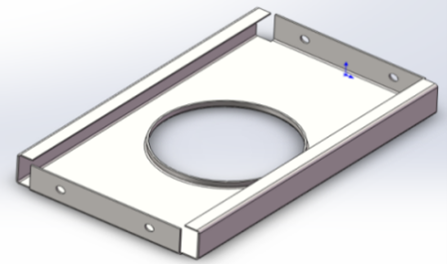

IV. Machine Details

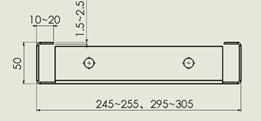

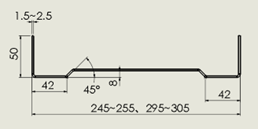

V. Profile Effect & Application