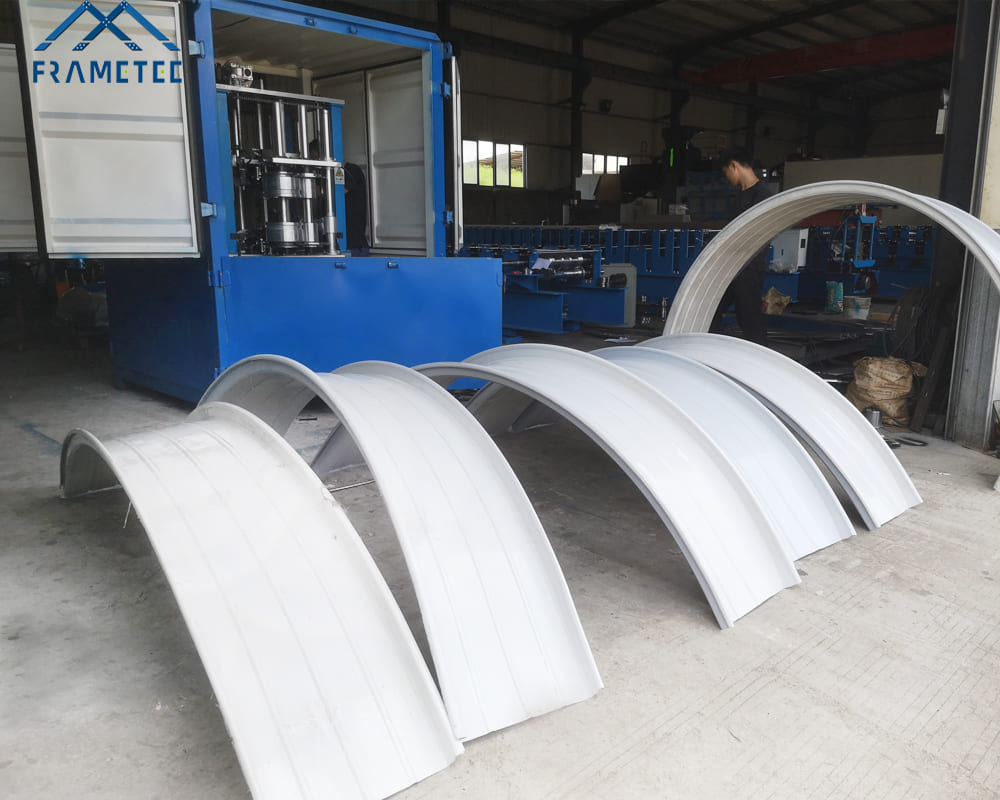

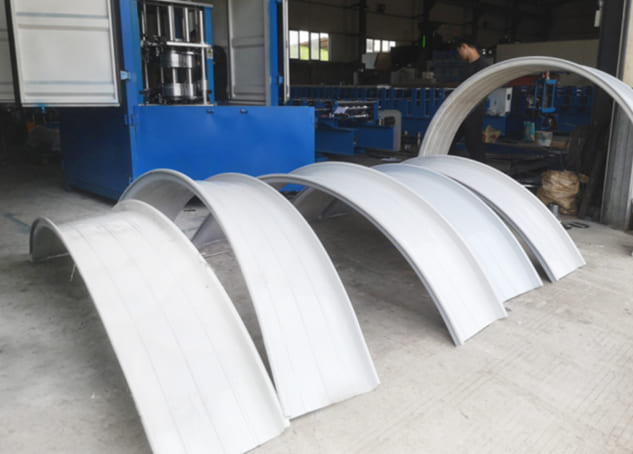

ZDWH65-400 Radius curved standing seam roof panel bending machine – This arc bending machine is specially tailored for curving finished sheet metal. The curved panels find extensive applications in various architectural designs, sports arenas, high-speed railway stations, museums, and more. This model accommodates positive, negative, and continuous curving, offering versatility in creating various arc shapes. Controlled by a computer system, it features a user-friendly touchscreen interface, CNC length control, automatic model switching, servo-driven swinging rollers, and roller gear transmission. The electrified control ensures easy operation, enhancing production efficiency while reducing manual labor intensity. Elevate your manufacturing capabilities with this advanced and customized arc bending machine.

..

Machine Part

Ⅰ、Specifications

| Machine model | ZDWH65-400 Radius curved standing seam roof panel bending machine |

| Expand width | 300-720mm |

| Material Thickness | 0.8-1.2mm, Q235mpa Aluminum magnesium manganese plate |

| Main Motor | 4KW |

| Production Control System | Self-devoloped Controlling Software |

| Production speed | 0-20m/min |

II. Machine Video

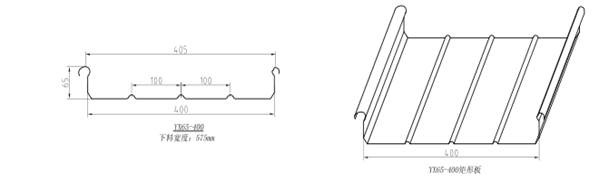

III.Profile details

The machine can bend plate specifications: the maximum straight plate type is 720mm, the minimum type is 300mm, and the specifications can be changed steplessly by computer operation during the period;

The maximum head of the fan-shaped plate is 600mm, and the minimum head is 200mm. When bending the fan-shaped plate, the machine specifications need to be adjusted to the maximum specification to make way. Bend one side first, then bend the other side after it comes out

The size of the bending arc depends on the material, thickness, and strength of the board. The radius of a single bending arc is slightly different. Please consult separately for special materials such as color steel plate, copper plate, galvanized plate, etc.

For example:

Aluminum magnesium manganese plate 3004, thickness 0.9mm, positive arc about 2.5m, reverse arc about 8m.

Aluminum magnesium manganese plate 3004, thickness 1.0mm-1.2mm, positive arc about 2m, reverse arc about 5m.

The extreme curvature of aluminum material is about 1.5 meters for forward bending and 8 meters for reverse bending. The steel material has a forward bend of about 8 meters and a reverse bend of 10 meters. If the arc value is less than the limit, the board will have bulges or wavy edges on both sides.

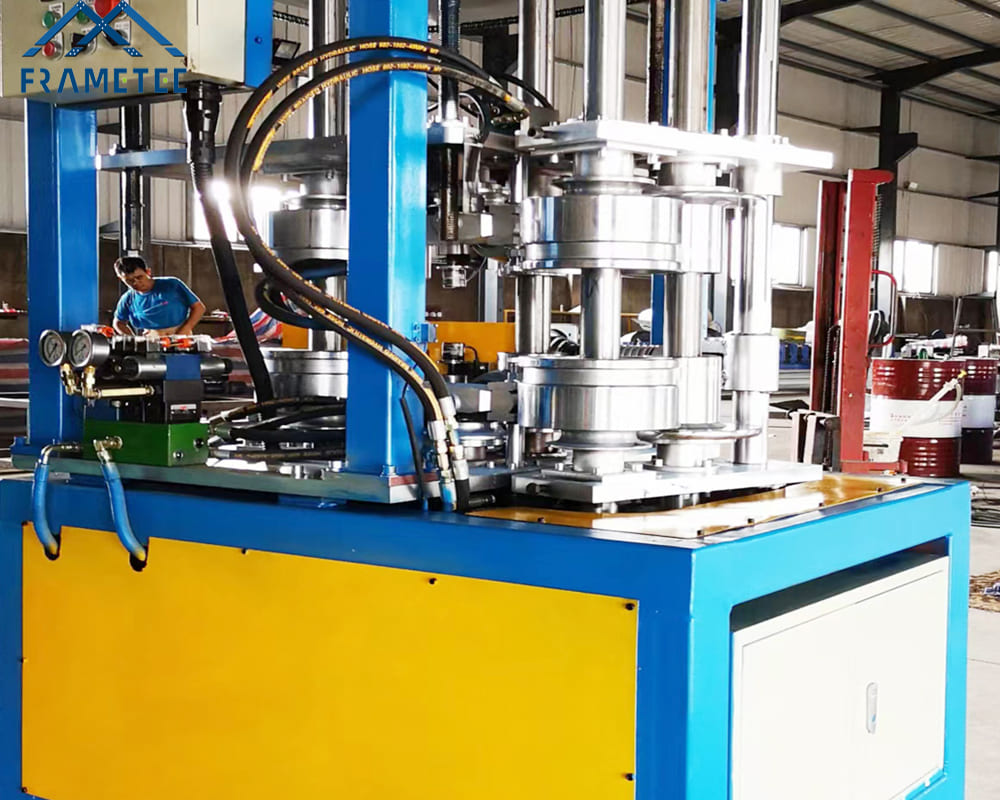

IV. Main Components:

A. Main arc bending machine——1 set:

1) The main machine is driven by a reducer with a power of 4KW, and the motor is installed inside the machine;

2). The model change motor is driven with a power of 0.55KW to achieve rapid model change. It takes about 2 minutes to switch from the largest model to the smallest model;

3) The servo motor drives the left and right swing of the curved roller, with a power of 2KW, using the INVT brand and precise positioning;

4), the roller material is 45#, some parts that are easy to wear are made of CR12 mold steel, CNC finishing, heat treatment HRC58°-60°, some rollers have embedded bearings; stress relief to ensure arc bending quality;

5). Spindle material is 40CR, diameter is 60mm, quenched and tempered, hard chrome plated after surface finishing, and processed by grinder;

6). Wall panel material is 45#, thickness 30mm, precision ground, surface hard chrome plated;

7). The whole machine adopts the national standard 10# square tube splicing frame to ensure strength, stability and safety.

B.Hydraulic system——1 set:

1). The oil pump motor power is 2.2KW, the hydraulic tank volume is 60L; the oil tank is built-in;

2) The system comes with an air cooling system to ensure long-term operation of the machine;

3). It adopts 4 sets of specially customized oil cylinders, which are individually controlled and regulated by 4 sets of solenoid valves. The advantages are convenience and stable oil circuit. The hydraulic system is controlled by the electronic control system and can operate at any time in conjunction with the plate advance; ensuring arc bending quality.

4) The oil pump adopts a Taiwanese precision gear pump, and the battery valve and other parts adopt Beijing Huade. The system has a pressure maintaining function; the working pressure is 10MPA, and the maximum pressure of the system is 20MPA.

C. PLC control system——1 set:

PLC Brand: Delta

Screen language: English/Chinese

Cut command :Yes

Profile length set-up :Yes

Batch quantity program :Yes

Low pressure electric part :Schneider brand

Encode :Japan Omron

Remark : set the number of radians (up to 20 different radians can be set for a single board), the size of the radian, the model size, etc.

Applications

Our Factory

Why Choose us:

14 years’ manufacturing experience in cold roll forming machine

Competitive price and good quality

One year free warranty

Fast response of after sale service

Can be customized by clients’ requirements

Easy operate and easy to maintain